CLEAR SPAN BUILDINGS

FILM & TV PRODUCTION

SOUND STAGES AND WORKSHOPS.

QUALITY

RELIABLE

EXPERIENCED

Clear Span are leading specialists in construction solutions working at the heart of the UK film studios facilities industry.

“The UK is home to many major film studios and sound stage production facilities and is also one of the world’s primary locations for global media players seeking to increase their output and make the most of the rise in online streaming.”

In 2019 top streaming players took long-term leases on stages and large-scale production accommodation in Buckinghamshire including the creation of a dedicated production hub. These long‑term leases, while significant for the UK TV and film industry, have led to a shortage of UK studio space.

Clear Span assists architects, developers, and studios to meet their requirements for new and existing studios providing top class sound stage and workshop buildings and infrastructure.

Media production networks and developers.

We offer studio and sound stage facilities consisting of:

Flat-floor TV Super-flat floor or shiny floor studios which are generally used for TV studios. They contain laser-levelled resin floors to enable smooth multi‑camera tracking, giving them a shiny, black-glass finish.

Sound attenuation and extreme height elephant access doors. We provide options for technical acoustic isolation proofing systems to the very highest decibel protection levels using the latest in high technology, low weight materials providing outstanding results on sound limiting, reverberation control levels while meeting fire regulations.

Lighting and equipment gantries in the form of either aerial walkways or a tensioned steel height adjustable grid maximising and managing the internal operational clear heights. These factors enable power flying or rigging as required and will accommodate production technical and broadcast cabling.

HVAC and MEP services that consider important sustainability targets and requirements of the local authorities and Building Control.

Sound Stages | Example Dimensions

20,000ft2 STAGE (1,859m)

126ft span x 158ft length x 50ft eave height (38.41m x 48.4m x 15.5m)

30,000ft2 STAGE (2,788m)

151ft span x 198ft length x 50ft eave height (46.17m x 60.4m x 15.5m)

40,000ft2 STAGE (3,718m)

184ft span x 218ft length x 50ft eave height (56m x 66.4m x 15.5m)

Loading data & gantries.

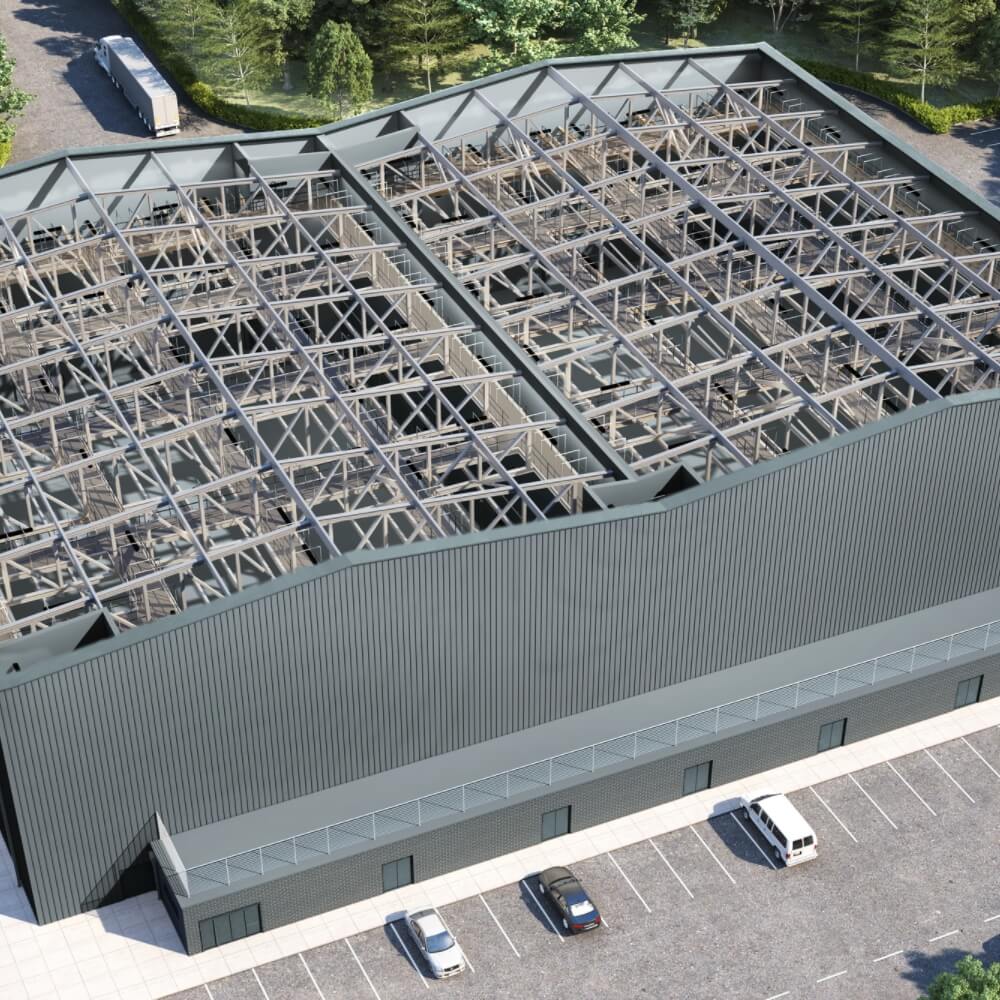

As well as the standard snow and service loads, we incorporate imposed roof loads of 1.5kN per mt. UDL within our hot form steel framework designs taken back to 6m x 6m grid producing extremely efficient point loading capabilities of 54kN per grid.

Fixed or suspended lighting and set equipment gantries. Our suspended gantry solutions lower to ground level for ease of equipment and lighting changes removing working at height constraints.

Stages cladding & the build envelope.

Double built-up cladding systems to the walls, internally cladded twin skin steel with 160mm fire compliant wool insulation creating 2 sets of 160mm wool insulation systems with an air cavity pocket for increased acoustic isolation performance. Double adjoining stage buildings located side by side benefit from an acoustic break design located in between each building producing maximum sound travel barrier efficiencies.

Sound attenuation linings reaching your decibel targets on reverb and sound isolation are installed to the inner cladding surface.

MEP Services & power fit out.

Clear Span provide dedicated designs and installations for all MEP solutions serving the sound stages and allied facilities including washrooms and plant stations.

There is generally a high demand for power in production stages and TV studios for lighting. Power demand can be up to 1MW in a standard 30,000ft2 production stage. The power can be provided via a dimmer room and duplicated within the stages. Power connectivity is typically delivered via a combination of various sized “commando” type sockets and Powerlock 400A connectors located into power panels strategically positioned for maximum convenience for the equipment and production companies’ occupancy.

Given the size of the electrical loads anticipated, a high-voltage (HV) power network is normally required. This allows a network of high and low voltage (HV/LV) transformers and switch rooms to be located close to the power demand to minimise LV cable runs. The capacity of electrical distribution equipment is generally sized for peak electrical loads, with the load profile tending to be extremely varied over the day.

A utility owned HV substation would be the point of connection to the site. Given the high electrical loads anticipated, utility providers can advise the developer on infrastructure or network upgrading.

We can advise on all MEP topics and provide a wide range of workable options to meet your budget.

Wide ranging HVAC services.

Clear Span can assist with your energy strategy which may be developed for the entire site. We provide solutions for heating, ventilation, and cooling. These include ground and air source heat pump systems for addressing the long-term economies of heating and cooling running costs. Dedicated systems are offered to our clients to suit each scenario and objective.

A popular method of ventilating or cooling a production stage is with the use of displacement ventilation, through low-level displacement outlets. An alternative is to install additional high-level displacement outlets to introduce top-down cooling into double-height open-top sets. Background heating can also be provided during stages downtime.

Clear Span steel mezzanine floors come with multiple column grid sizes depending on the available area we would be working with.

Typically, we install standalone mezzanines that are free standing inside our workshop buildings, with either single layer flooring or fire wall under layer depending on the activities that will be carried out inside the workshop. Steel staircases and loading gates and safety fences are all part of our mezzanine packages and we work closely with your requirements.

Steel mezzanine floor systems doubling your workshop returns.

Clear Span steel mezzanine floors come with multiple column grid sizes depending on the available area we would be working with.

Typically, we install standalone mezzanines that are free standing inside our workshop buildings, with either single layer flooring or fire wall under layer depending on the activities that will be carried out inside the workshop. Steel staircases and loading gates and safety fences are all part of our mezzanine packages and we work closely with your requirements.

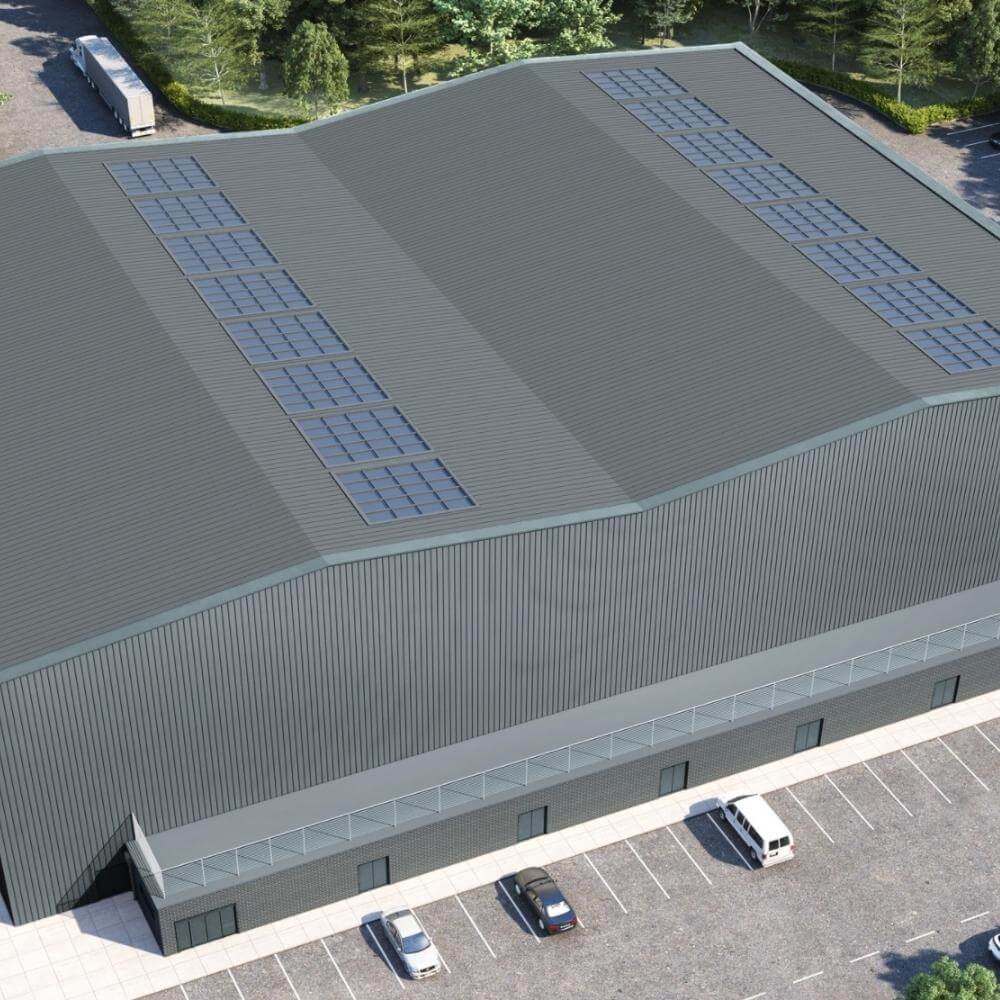

Sustainability – building regulations and local planning policies.

Clear Span are well equipped for addressing these items and carbon reduction plays a significant role on most developments, partly because of local authority planning policies. It is not uncommon, for example, to see requirements for new-builds to meet a 15% carbon reduction in the “be lean” category and up to 35% reductions overall.

We can assist on these targets through various design options at the start of the client brief and take things forward to include the needs and requirements of the local authorities. Meeting these targets requires careful consideration during design to ensure energy efficiency is embedded in areas such as building fabric (U-values), airtightness, heat recovery and low specific fan power (SFP) for air-handling units and of course efficient lighting design. We can apply consideration to the potential use of photovoltaics and air or ground source heat pumps to achieve the planning policy requirements of your local council or overall carbon savings.

Workshops for set manufacture, costume production & special effects.

Clear Span staff have been involved in the design, supply, and installation of literally tens of thousands of square metres of film production workshops over many years for all the major UK film studios.

We co-ordinate and work at the very heart of the studios “Mill” providing either temporary demountable quick-up workshops, or we can design and build hot and cold formed steel longer term workshops, that are fully compliant with Building Regulations. Typical facilities range from 25m wide down to 10m wide and come with or without internal power installations and lighting and heating packages. We can make standard workshops look very sleek and in keeping with the ambience of your studio’s facilities.

Dedicated 3 phase power panels can be installed to make even the highest demands of a set design welding workshop run smoothly, along with LED lighting and GSHP units to keep the workshops heated at the lowest possible running costs. Additional items such as multiple opening double-glazed window units, large and small powered roller shutter doors and steel double and single personnel doors. We make our workshops a good place to work, and that results in your tenants being happy and extending leases!

Outstanding levels of client service.

We thrive on tight construction schedules, and all studios encounter daily pressurised situations with deadlines that are highly urgent. We will help you achieve the impossible, in a consultative and supporting manner making your project succeed on programme and stay on budget. Our qualified project managers are determined to provide high standards of support and we go the extra mile to ensure our targets are met on customer service and technical support.

Shinfield Studios, Reading

“We are delighted to be working with Clear Span as they help us to deliver one of the UK’s largest and most modern Studio facilities. Their reliable and professional approach coupled with a desire to push construction boundaries makes them our first-choice supplier”.

Nick Smith

Managing Director